Business leaders often confuse logistics with supply chain management, leading to costly inefficiencies and missed opportunities. Without a clear understanding, technology choices can be disconnected, leading to delays and making it harder to manage daily work.

Understanding the difference between logistics and supply chain management is crucial to addressing these issues. Logistics manages the daily movement and storage of goods, while supply chain management connects each step from sourcing materials to final delivery, guided by long-term strategy.

In this blog, we will break down the distinctions between logistics and supply chain management, explain how each supports business goals, and guide you on choosing the right software strategy to improve operations and prepare for future growth.

Key Takeaways

- Logistics manages daily operations related to the movement and storage of goods.

- Supply chain management oversees the entire flow from suppliers to customers, utilizing strategic planning.

- Logistics decisions focus on immediate execution, while supply chain decisions emphasize long-term coordination.

- Technology supports logistics through automation and tracking, and aids the supply chain with forecasting and partner collaboration.

- Effective software choices align with business goals and internal capabilities, striking a balance between operational needs and strategic growth.

What Is Logistics and How Does It Work?

Logistics serves as the operational engine that moves products from point A to point B. This function handles the physical aspects of delivering goods to their designated locations, at the optimal time and the lowest possible cost.

Logistics involves several tightly connected processes that keep goods moving efficiently:

- Transportation management – Planning and managing the movement of goods across road, rail, air, or sea. This includes carrier selection, route planning, scheduling, and real-time shipment tracking.

- Warehouse operations – Receiving inventory, organizing it for storage, and preparing it for delivery. Activities such as picking, packing, and staging must be completed with speed and accuracy.

- Order fulfillment – Coordinating inventory allocation, packaging, labeling, and carrier dispatch once an order is received. Timing and system coordination are key to meeting delivery expectations.

- Inventory control – Tracking stock levels, forecasting short-term demand, and scheduling timely replenishment to avoid overstocking or shortages.

- System integration – Connecting transportation, warehousing, and order systems to enable real-time visibility, automation, and smooth handoffs across each function.

Logistics succeeds when these processes operate in sync. It is a fast-moving, detail-driven function that keeps daily operations running and supports the broader supply chain.

What Is Supply Chain Management and How Does It Work?

Supply chain management integrates functions like procurement, production, warehousing, transportation, and demand forecasting through centralized planning platforms and cross-functional teams to ensure seamless coordination from raw materials to customer delivery.

Instead of focusing on individual tasks, supply chain management connects suppliers, manufacturers, logistics providers, and retailers into a single, coordinated network. The goal is to enhance efficiency, mitigate risk, and ensure that every component of the system works in harmony to meet customer demand.

Here is how supply chain management works in practice:

- Network design – Deciding where to place suppliers, production facilities, and warehouses based on cost, capacity, and customer locations.

- Supplier coordination – Building long-term relationships with vendors who can consistently meet quality, pricing, and delivery expectations.

- Demand forecasting – Using historical data, market trends, and real-time signals to predict how much product will be needed and when.

- Inventory and production planning – Aligning inventory levels and manufacturing schedules with forecasted demand to prevent overstocking or shortages.

- Risk and disruption management – Preparing for delays, shortages, or external events by implementing contingency plans such as alternative sourcing, safety stock, and flexible logistics networks.

- Performance tracking – Monitoring cost, speed, service quality, and sustainability across all stages of the supply chain.

Supply chain management is effective when each of these components is connected through shared data, well-defined processes, and clear communication among partners.

Logistics vs Supply Chain Management: Key Differences That Matter

Many companies confuse logistics and supply chain management because both involve the movement of products. However, they operate at different levels and serve distinct purposes. Logistics handles daily execution. Supply chain management plans the entire system that enables execution.

To see the difference clearly, you have to look at how they function across specific areas:

Scope and responsibilities

Logistics focuses on what happens inside the business. It covers shipping, warehousing, inventory control, and order fulfillment. A logistics manager makes sure deliveries arrive on time and warehouses run smoothly.

Supply chain management covers a broader network. It involves working with suppliers, contract manufacturers, third-party logistics partners, and even retailers. Supply chain leaders shape how the whole system operates, not just the tasks inside one organization.

Timeframe

Logistics works on a short timeline. Teams plan today’s shipments, assign trucks, monitor inventory levels, and respond to issues as they come up. Every decision is tied to immediate execution.

Supply chain management looks further ahead. It involves supplier contracts for the upcoming year, future warehouse capacity, or sourcing plans for the following product line. The focus shifts from daily activity to long-term planning.

Focus of decisions

Logistics teams work within the existing system. They focus on execution: how to load trucks more efficiently, reduce packing time, or enhance delivery accuracy. These are short-cycle decisions that keep daily operations moving.

Supply chain teams design the logistics of the system. They decide which suppliers to work with, where to place warehouses, and how to structure the flow of goods. These choices shape long-term operations and create the framework that logistics teams follow.

Integration and systems

Logistics systems facilitate coordination within a single company. For example, warehouse software can link to transportation tools and inventory trackers, enabling internal teams to manage shipping and storage without requiring input from outside partners.

Supply chain systems support coordination between multiple organizations. These platforms connect manufacturers, suppliers, distributors, and retailers. They help teams forecast demand, plan production, and manage supplier relationships across the entire network.

Use of data

Logistics teams utilize data to track daily activities. They track delivery times, shipping delays, stock movements, and warehouse performance. This helps them make quick adjustments when orders pile up, inventory runs low, or routes need to change.

Supply chain teams rely on long-range data to support planning and design. They analyze supplier lead times, production capacity, demand trends, and market changes. Their focus is on building a supply system that can stay stable and flexible over time.

The core difference lies in ownership. Logistics teams manage the physical movement of goods, determining where, when, and how they are transported. Supply chain teams design the larger system that enables this movement. One runs the engine. The other builds the machine. Companies that treat them as separate but connected functions avoid waste, stay responsive, and make better decisions under pressure. When these roles blur or break, even simple problems can derail the entire operation.

Role of Technology in Logistics and Supply Chain Management

Technology plays a central role in how companies move products and manage complexity. In logistics, it drives execution by automating tasks and improving speed. In supply chain management, it supports planning, forecasting, and coordination across suppliers and partners.

Since each function addresses a different problem, the tools and platforms it relies on serve various purposes. The breakdown below shows how technology supports each side.

How Technology Powers Logistics

- Warehouse automation systems: In high-volume warehouses, robotic arms, conveyor belts, and scanning tools automate manual tasks such as picking, packing, and sorting. This enables logistics teams to process more orders with fewer errors and a faster turnaround.

- Transportation management platforms: These systems plan routes, assign loads, and coordinate with carriers across regions. Dispatchers utilize them to minimize empty miles, prevent delays, and optimize fleet performance in real-time.

- Operational dashboards: Logistics managers rely on centralized dashboards to track shipment progress, warehouse activity, and order flow across multiple sites. When a delivery is late or inventory is low, alerts flag the issue early.

- Integrated logistics systems: Connections between warehouse software, inventory databases, and shipping tools let teams sync actions without re-entering data. For example, when stock levels drop, a trigger can initiate replenishment automatically.

How Technology Supports Supply Chain Strategy

- Control tower software: These are centralized platforms that pull real-time data from suppliers, factories, carriers, and distributors. Planners use them to track inventory levels, shipment statuses, and production capacity across the entire network. This visibility enables teams to identify disruptions early and coordinate responses across stakeholders.

- Demand sensing tools: Planners use these systems to track real-time sales, weather, promotions, and local market changes. Instead of relying on static forecasts, they can adjust their inventory and production based on current events.

- AI monitoring systems: Risk detection engines scan delivery data, supplier performance, and capacity shifts to spot early signs of disruption. They help teams act before delays or shortages spread across the network.

- Shared ledgers for supply partners: Blockchain-backed records give all parties access to shipment updates, contract terms, and compliance logs. That means fewer disputes, faster payments, and less manual reconciliation.

Current Challenges in Logistics and Supply Chain Execution

Every business runs into obstacles when moving products and managing complex supply chains. Knowing what these challenges are helps companies focus on the right fixes before minor issues become big problems. Let us examine some common challenges in logistics and supply chain management, along with practical solutions to address them.

Logistics Challenges

Logistics teams encounter several issues that hinder day-to-day operations. Many companies use separate systems for managing warehouses, transportation, and inventory, which creates data silos and slows decision-making. Older technology often lacks the necessary connectivity for quick updates, resulting in delays caused by manual data entry.

At the same time, shortages of drivers and warehouse workers limit capacity and increase pressure on existing staff. Navigating complex regulations across different regions also adds hurdles that can disrupt shipments. In addition to all that, cyberattacks and ransomware pose significant threats to operations and data security.

Solutions for Logistics Challenges

- Integrate logistics systems to enable real-time data sharing and reduce information gaps.

- Upgrade to modern, cloud-based platforms with APIs to automate data exchange and speed up processes.

- Adopt warehouse automation and improve route planning to ease labor shortages.

- Utilize compliance management software that automatically updates regulatory requirements related to transportation safety, customs, and environmental standards to ensure ongoing adherence.

- Strengthen cybersecurity protocols and train employees regularly to defend against attacks.

Supply Chain Management Challenges

Supply chain managers face several challenges that affect long-term planning and strategy. Limited visibility beyond their operations makes it hard to identify risks from suppliers or sudden changes in customer demand. Markets shift quickly, and without timely information, forecasting becomes unreliable.

Additionally, new environmental regulations require supply chains to reduce their carbon footprint and adopt more sustainable practices. At the same time, the demand for skilled professionals in analytics, technology, and global trade is growing, creating noticeable talent gaps. To make matters more complex, security risks go beyond individual companies and impact data sharing and collaboration across the entire network.

Solutions for Supply Chain Challenges

- Implement control tower platforms to gain real-time visibility across suppliers, production, and distribution.

- Utilize demand sensing tools that incorporate live sales data and external factors for more accurate forecasting.

- Integrate sustainability metrics into supply chain planning and supplier assessments.

- Invest in training and partner with specialists to close talent gaps.

- Employ blockchain and secure collaboration tools to protect data shared among partners.

Choosing the Right Software Strategy: Logistics, SCM, or Both?

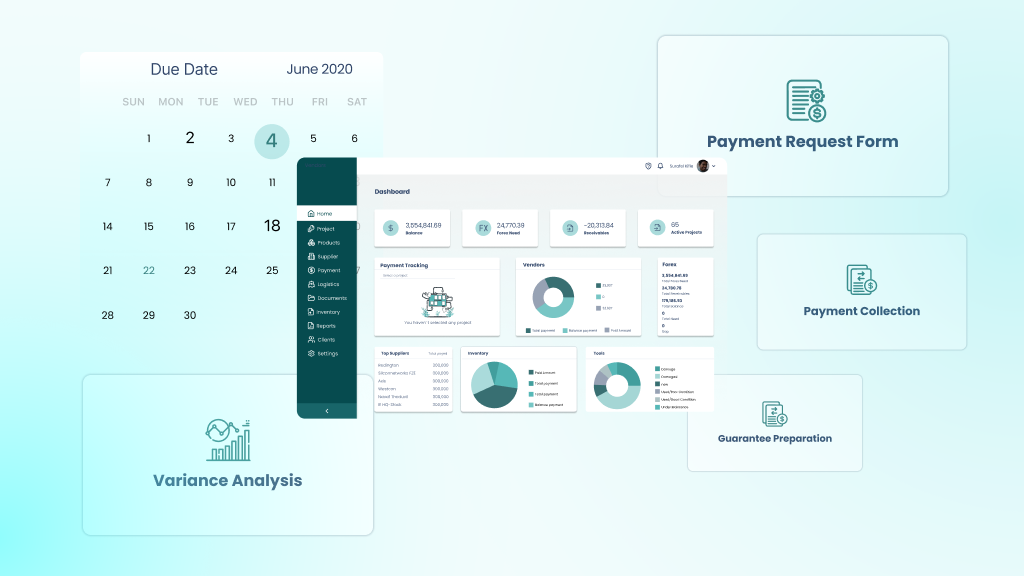

Selecting the right software starts with your business goals. Logistics software enhances daily operations, including transportation and warehousing, while supply chain management platforms facilitate broader strategies, such as demand forecasting and supplier collaboration.

Begin by evaluating your current systems and how well they connect. If your logistics tools are strong, adding supply chain features can provide greater visibility. Newer businesses may find that combined platforms, which handle both logistics and supply chain tasks, are more effective.

Different industries have unique demands. Fast-moving consumer goods require software that can handle high-volume processing. Manufacturers and e-commerce companies require solutions tailored to specific regulations and operational challenges.

Internal capabilities also matter. Supply chain software relies on advanced analytics and process management. If those skills are limited, starting with logistics improvements and expanding later is a practical approach.

To support growth, look for scalable, cloud-based systems that integrate smoothly with your existing applications. Flexible, API-driven platforms help keep your technology future-proof. DEVtrust specializes in delivering customized software that bridges operational logistics with strategic supply chain management. It is evident from their completed projects that DEVtrust understands the challenges businesses face.

Their solutions offer real-time tracking for shipment control, route planning to minimize costs, and fleet automation to enhance efficiency. All are designed to fit your current systems and scale with your business. This approach ensures operational reliability today and strategic insight for tomorrow, helping companies stay competitive in growing markets.

Conclusion

The distinction between logistics and supply chain management shapes how organizations approach operational improvement and technology investment. Logistics delivers tactical excellence in moving and storing goods, while supply chain management provides strategic coordination across the entire value delivery network.

Companies that recognize these differences build more effective operational strategies. They invest in logistics technology to optimize current operations while developing supply chain management capabilities to drive long-term competitive advantage. This dual approach creates sustainable performance improvements that competitors struggle to replicate.

Modern business success requires both operational excellence and strategic agility. Organizations require logistics systems that deliver reliable and cost-effective execution, alongside supply chain management platforms that enable rapid adaptation to changing market conditions.

If you are ready to build logistics and supply chain management solutions, then get in touch with us to discuss custom platform development that aligns technology investments with business objectives.

Difference Between Logistics and Supply Chain Management

Understand logistics vs supply chain management. Discover key differences, core functions, technology roles, and industry's future. Click to learn more!

Contact Us